Polymer Systems

Technology Limited

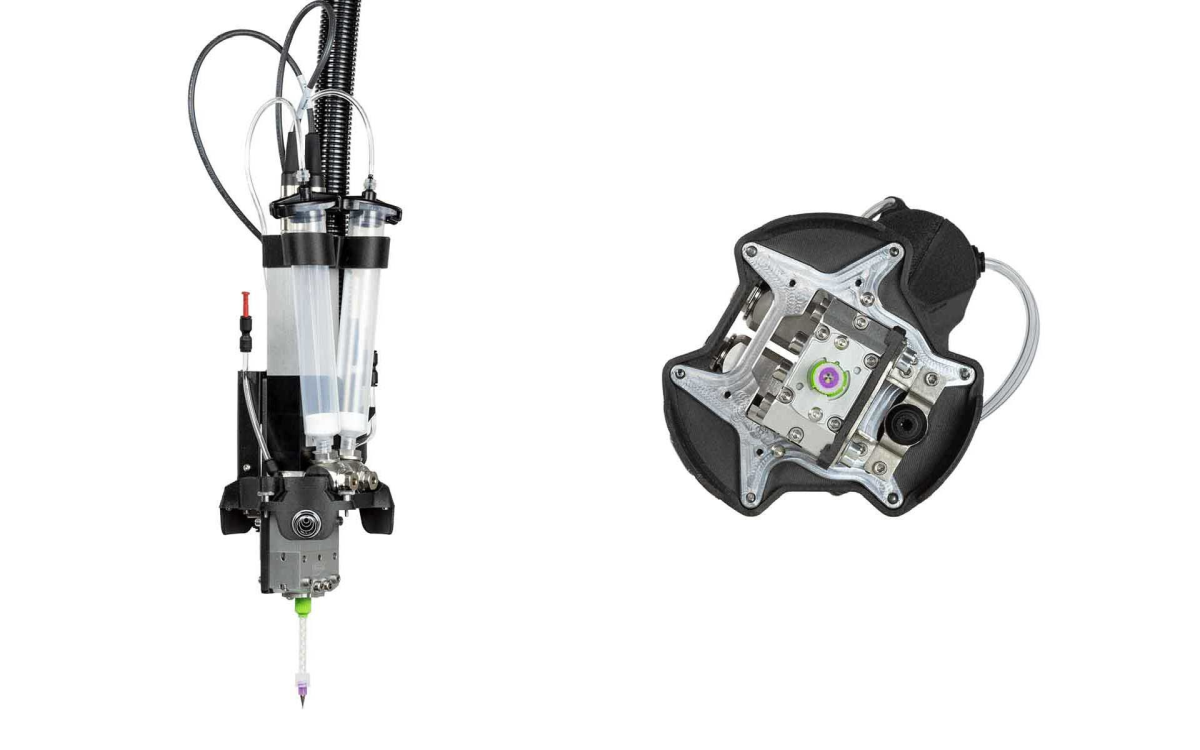

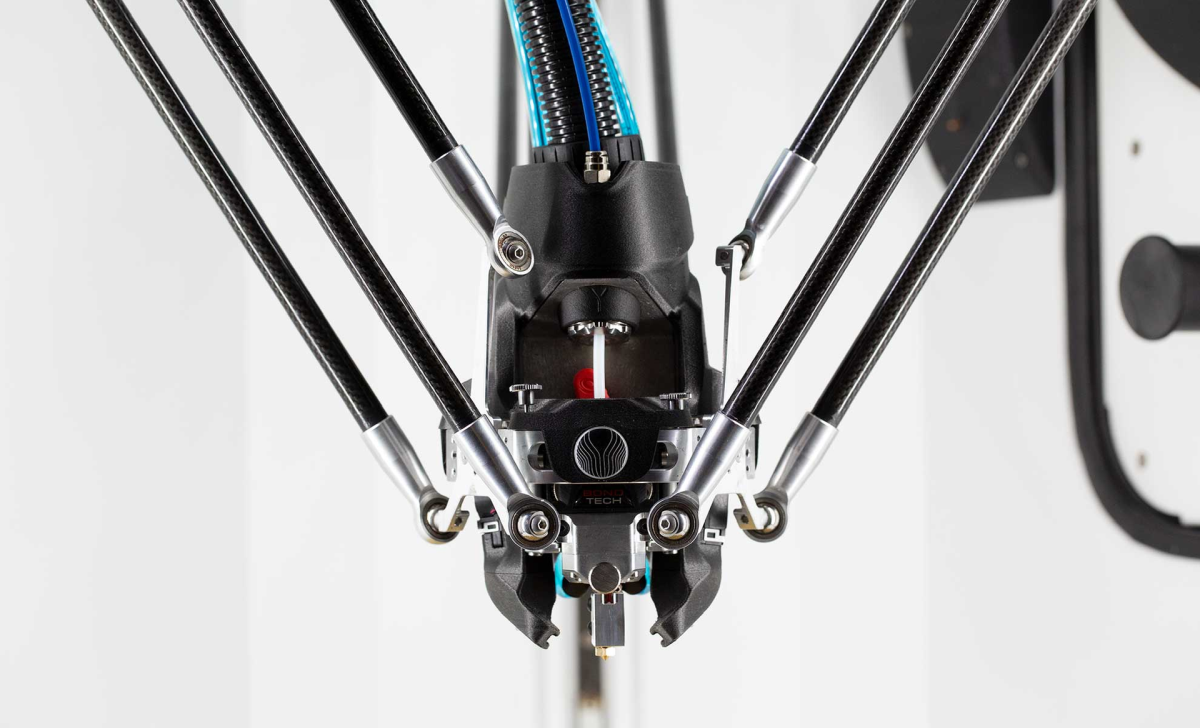

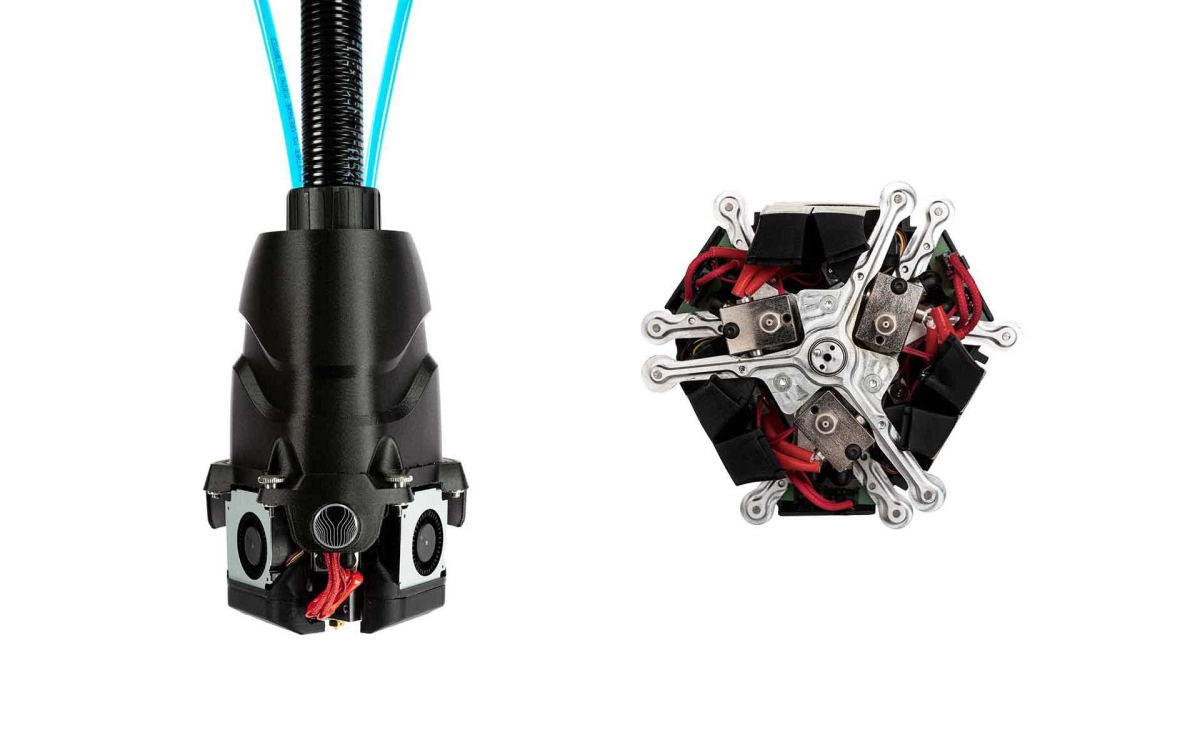

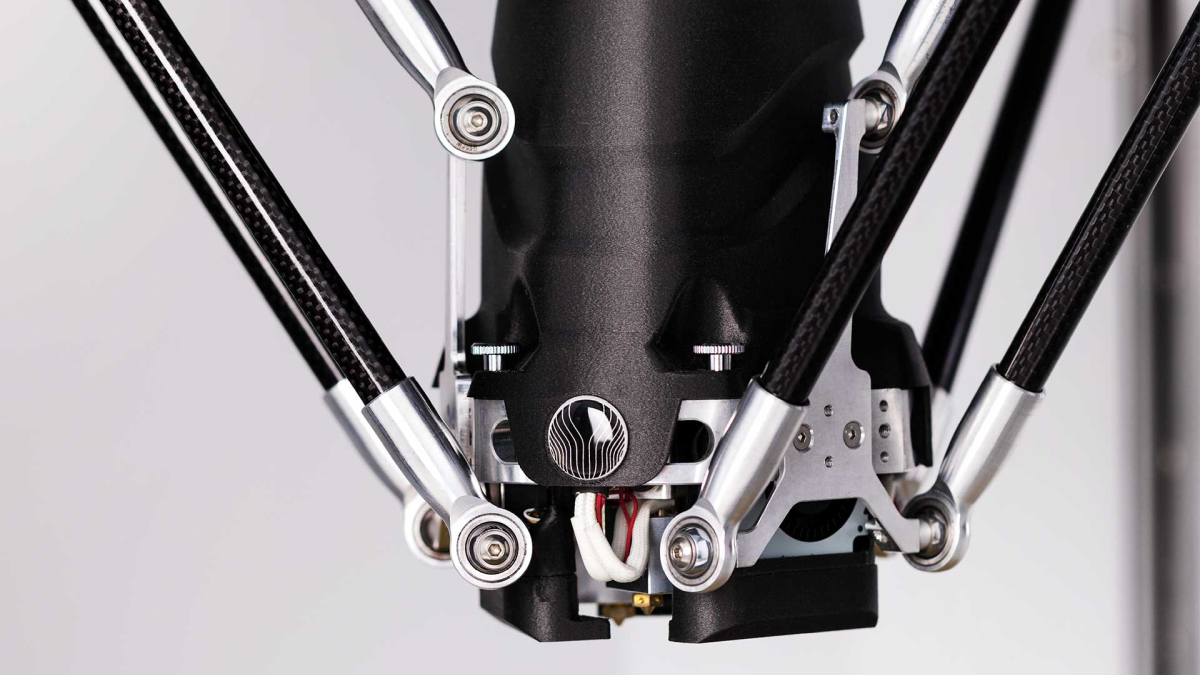

S600D

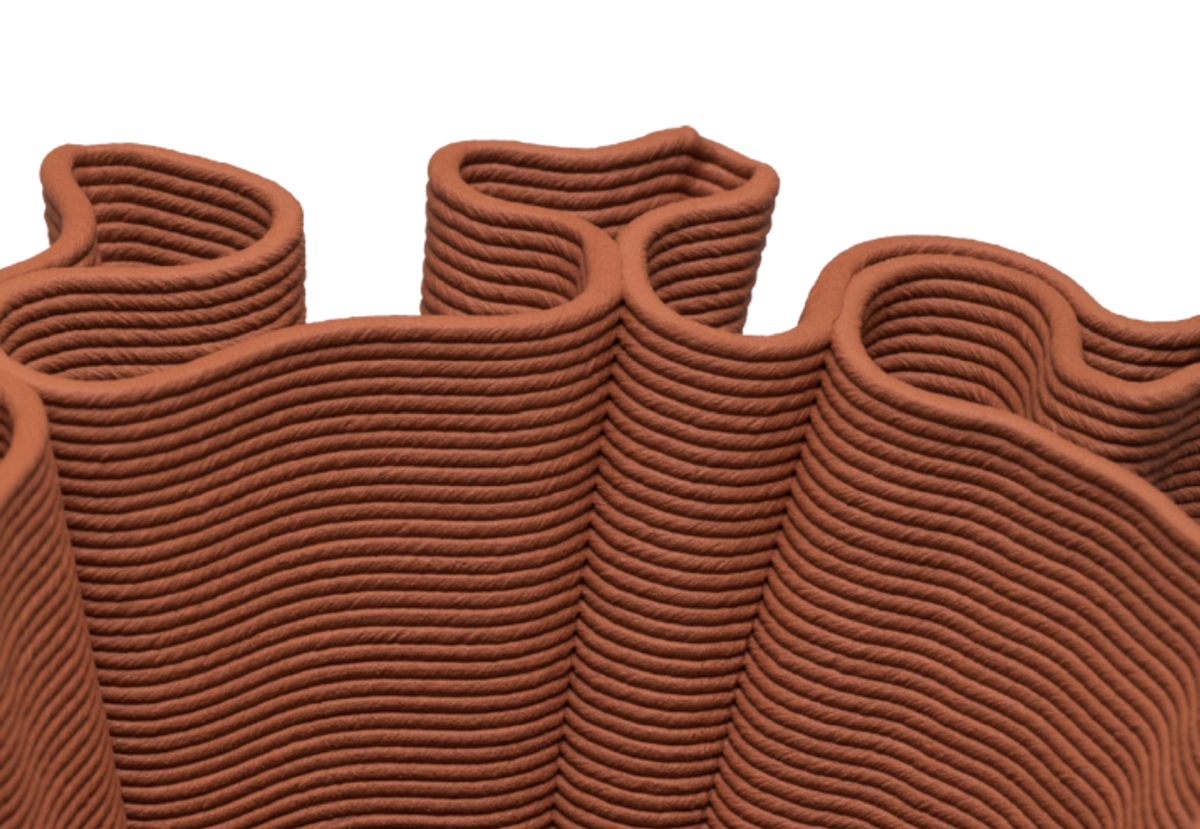

The S600D is a one-of-a-kind 3D printer. Its quick-change toolhead technology allows you to set up and print with the toolhead and nozzles of your choice in a matter of just minutes. For a new print project in a different material, simply change the toolhead.