Transmission and absorption data available.

LS - Product listing

LS-6140 » Optical Thermoset

| Typical Properties | Result | Metric Conv. |

| Uncured: | ||

| Appearance | Colorless and Transparent | - |

| Viscosity, Part A | 3,700 cP | 3,700 mPas |

| Viscosity, Part B | 2,550 cP | 2,550 mPas |

| Work Time | 3 hours | - |

| Tack-Free Time | 6 hours | - |

| Cured: 15 minutes at 150°C (302°F) | ||

| Specific Gravity | 1.02 | - |

| Durometer, Type A | 50 | - |

| Tensile Strength | 850 psi | 5.9 MPa |

| Elongation | 90% | - |

| Lap Shear Strength (primed w/ LS1-3200) | 200 psi | 1.4 MPa |

| Coefficient of Linear Thermal Expansion, above Tg (-80 to 250°C) | 400 ppm/°C | - |

| Refractive Index, 589 nm | 1.4 | - |

| TGA Takeoff (1% weight loss) | 353°C | - |

| Dielectric Strength | 520 volts/mil | 20.5 kV/mm |

| Volume Resistivity | 1 x 1015 ohm cm | - |

| Thermo-optic Coefficient | -3.36 x 10-4/°C | - |

| Ionic content, Cl | <5ppm | - |

| Ionic content, K | <2ppm | - |

| Ionic content, Na | <4ppm | - |

| Refractive Index vs. Wavelength | See Profile PDF | - |

| Optical Absorption vs. Wavelength | See Profile PDF | - |

LS-6941 » Optical Thermoset

| Typical Properties | Result | Metric Conv. |

| Uncured: | ||

| Appearance | Transparent | - |

| Viscosity | 5,800 cP Part A / 90 cP Part B | 5,800 mPas Part A / 90 mPas Part B |

| Viscosity (Parts A and B mixed) | 5,300 cP | 5,300 mPas |

| Work Time | 5 hours | - |

| Tack-Free Time | 15 hours | - |

| UV/Visible Spectrophotometry at 400 nm 1 cm path length | 98% Transmittance | - |

| Cured : Cured 15 min at 150°C (302°F) | ||

| Specific Gravity | 1.03 | - |

| Durometer, Type A | 50 | - |

| Tensile Strength | 1,300 psi | 9.0 MPa |

| Elongation | 95% | - |

| Tear Strength | 20 ppi | 3.5 kN/m |

| Refractive Index, 589 nm | 1.41 | - |

| Dielectric Strength | 500 volts/mil | 19.7 kV/mm |

| Volume Resistivity | 1 x 1015 | - |

| Thermooptic Coefficient | -3.5 x10-4/°C | - |

| Refractive Index vs. Wavelength | See Profile PDF | - |

| Optical Absorption vs. Wavelength | See Profile PDF | - |

LS-6943 » Optical Thermoset

| Typical Properties | Result | Metric Conv. |

| Uncured: | ||

| Appearance | Transparent | - |

| Viscosity | 5,400 cP | 5,400 mPas |

| Cured : 60 min at 100°C (212°F) | ||

| Specific Gravity | 1.03 | - |

| Durometer, Type A | 40 | - |

| Tensile Strength | 900 psi | 6.2 MPa |

| Elongation | 120% | - |

| Refractive Index, 589 nm | 1.43 | - |

| Thermooptic Coefficient | -3.9 x 10-4/°C | - |

| Refractive Index vs. Wavelength | See Proflie PDF | - |

| Optical Absorption vs. Wavelength | See Proflie PDF | - |

LS-6946 » Optical Thermoset

| Typical Properties | Result | Metric Conv. |

| Uncured: | ||

| Appearance | Translucent | - |

| Viscosity, Part A | 40,000 cP | 40,000 mPas |

| Viscosity, Part B | 35,000 cP | 35,000 mPas |

| Work Time | 2 hours minimum | - |

| Cured : 30 min at 150°C (302°F) | ||

| Specific Gravity | 1.14 | - |

| Durometer, Type A | 30 | - |

| Tensile Strength | 675 psi | 4.7 MPa |

| Elongation | 275 % | - |

| Tear Strength | 40 ppi | 7.1 kN/m |

| Lap Shear (primed w/ LS1-3200) | 510 psi | 3.5 MPa |

| Coefficient of Linear Thermal Expansion, | ||

| above Tg (-80 to 250°C) | 360 ppm/°C | - |

| TGA Takeoff (1% weight loss) | 715°F | 365°C |

| Extractable Ionics | Below MIL-STD-883E | - |

| Young's Modulus | 425 psi | 2.9 MPa |

| Dielectric Strength | 510 volts/mil | 20.1 kV/mm |

| Refractive Index, 589 nm | 1.46 | - |

| Refractive Index vs. Temperature, 589 nm | -3.3 x 10-4/°C | - |

| Refractive Index vs. Wavelength | See Profile PDF | - |

| Optical Absorption vs. Wavelength | See Profile PDF | - |

| Operating Temperature Range | -85 to 465°F | -65 to 240°C |

LS1-6140 » Optically Clear Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance | Colorless and Transparent |

| Viscosity, Part A | 3,450 cP (3,450 mPas) |

| Viscosity, Part B | 2,500 cP (2,500 mPas) |

| Viscosity, Mixed (V1) within 30 minutes of catalyzation | 3,200 cP (3,200 mPas) |

| Viscosity, Mixed (V2) 24 hours after catalyzation | 3,600 cP (3,600 mPas) |

| Viscosity, (V2/V1) 24 hours after catalyzation | 1.1 |

| UV/Visible Spectrophotometry at 400nm | 99%T |

| Cured: 60 minutes at 150°C (302°F) | |

| Specific Gravity | 1.02 |

| Durometer, Type A | 50 |

| Tensile Strength | 900 psi (6.2 MPa) |

| Elongation | 90% |

| Lap Shear Strength (primed with LS1-3200) | 270 psi (1.9 MPa) |

| Volume Resistivity* | 1.3 X 1015 ohm cm minimum |

| Dielectric Strength* | 630 V/mil (13.8 kV/mm) |

| Ionic Content, Cl* | < 5ppm |

| Ionic Content, K* | < 2.5 ppm |

| Ionic Content, Na* | < 2.5 ppm |

| Glass Transition Temperature (Tg)* | -115 °C (-175°F) |

| Coefficient of Linear Expansion (-150 °C to -120°C)* | 99 ppm/°C (99µm/(m°C)) |

| Coefficient of Linear Expansion (-100 °C to 100°C)* | 330 ppm/°C (330µm/(m°C)) |

| Refractive Index, 589 nm | 1.4 |

| Transmittance vs. Wavelength (25°C) | See Profile PDF for Graph |

| Refractive Index vs. Wavelength (25°C) | See Profile PDF for Graph |

| Refractive Index vs. Temperature by Wavelength | See Profile PDF for Graph |

*These properties NOT tested on a lot-to-lot basis. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

Recommended Primer LS1-3200

Note: Some bonding applications may require the use of a primer.

LS1-6941 » Optical Thermoset

| Typical Properties | Result | Metric Conv. |

| Uncured: | ||

| Appearance | Transparent | - |

| Viscosity, Part A | 75,000 cP | 75,000 mPas |

| Viscosity, Part B | 50,000 cP | 50,000 mPas |

| Refractive Index, Part A | 1.41 | - |

| Refractive Index, Part B | 1.41 | - |

| Work Time | >24 hours | - |

| Cured: 30 minutes at 150°C (302°F) | ||

| Specific Gravity | 1.03 | - |

| Durometer, Type A | 50 | - |

| Tensile Strength | 750 psi | 5.2 MPa |

| Elongation | 305% | - |

| Tear Strength | 80 ppi | 14.1 kN/m |

| Refractive Index vs. Wavelength | See Profile PDF for Graph | - |

| Optical Absorption vs. Wavelength | See Profile PDF for Graph | - |

LS2-6140 » Optically Clear Primerless Silicone Encapsulant

| TYPICAL PROPERTIES | AVERAGE RESULT |

| Uncured: | |

| Appearance | Colorless and Transparent |

| Viscosity, Part A | 3,100 cP |

| Viscosity, Part B | 2,300 cP |

| Viscosity, Mixed | 3,000 cP |

| Cured: 60 minutes at 150°C (302°F) | |

| Durometer, Type A | 47 |

| Tensile Strength | 940 psi (6.5 MPa) |

| Elongation | 125 % |

| Refractive Index at 589 nm | 1.41 |

| Volatile Content (1 hour at 275°C) | 0.7% |

| Glass Transition Temperature (Tg) * | -115°C |

| Coefficient of Linear Expansion (-100°C to 100°C)* | 330 ppm/°C (330µm/m°C) |

| Lap Shear to Aluminum (unprimed) | 390 psi (2.7 MPa) |

| Die Shear | 1.1 N/mm2 |

| Dielectric Constant, 100 Hz* | 2.80 |

| Dielectric Constant, 1 kHz* | 2.80 |

| Dissipation Factor, 100 Hz* | 0.0004 |

| Dissipation Factor, 100 kHz* | 0.0006 |

| Dielectric Strength* | 660 V/ml (25.7 kV/mm) |

| Volume Resistivity* | 1.1 X 1015 ohm cm |

| Ionic Content, Na * | <2.5 ppm |

| Ionic Content, K * | <2.5 ppm |

| Ionic Content, Cl* | <5 ppm |

| Tested per UL-94 (3.7 mm average thickness)* | V-0 |

| Recommended cure time guidelines at various temperatures* | |

| T90 at 80°C | 85 minutes |

| T90 at 100°C | 25 minutes |

| T90 at 120°C | 18 minutes |

*These properties NOT tested on a lot-to-lot basis. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

WARRANTY INFORMATION

The warranty period provided by Polymer systems Technology ltd (hereinafter “PST”) is 12 months from the date of shipment when stored below 40°C in original unopened containers. Unless PST provides a specific written warranty of fitness for a particular use, PST’s sole warranty is that the product will meet PST’s then current specification. PST specifically disclaims all other expressed or implied warranties, including, but not limited to, warranties of merchantability and fitness for use. The exclusive remedy and PST’s sole liability for Packaging Warranty 50 mL Side-by-Side Kit 12 Months 200 mL Side-by-Side Kit 400 ml Side-by-Side Kit 2 Pint Kit (910 g) 2 Gallon Kit (7.28 kg) 10 Gallon Kit (36.4 kg), Inc. All rights reserved. Trademarks are owned by PST or its affiliates unless otherwise noted. breach of warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted. PST expressly disclaims any liability for incidental or consequential damages.

WARNINGS ABOUT PRODUCT SAFETY

PST believes, to the best of its knowledge, that the information and data contained herein are accurate and reliable. The user is responsible to determine the material’s suitability and safety of use. NuSil Technology cannot know each application’s specific requirements and hereby notifies the user that it has not tested or determined this material’s suitability or safety for use in any application. The user is responsible to adequately test and determine the safety and suitability for their application and NuSil Technology makes no warranty concerning fitness for any use or purpose. PST has completed no testing to establish safety of use in any medical application. PST has tested this material only to determine if the product meets the applicable specifications. (Please contact PST for assistance and recommendations when establishing specifications.) When considering the use of PST products in a particular application, review the latest Material Safety Data Sheet and contact PST with any questions about product safety information. Do not use any chemical in a food, drug, cosmetic, or medical application or process until having determined the safety and legality of the use. The user is responsible to meet the requirements of the U.S. Food and Drug Administration (FDA) and any other regulatory agencies. Before handling any other materials mentioned in the text, the user is advised to obtain available product safety information and take the necessary steps to ensure safety of use.

PATENT / INTELLECTUAL PROPERTY WARNING

PST disclaims any expressed or implied warranty against the infringement of any domestic or international patent/intellectual property right. PST does not warrant the use or sale of the products described herein will not infringe the claims of any domestic or international patent/intellectual property right covering the product itself, its use in combination with other products, or its use in the operation of any process.

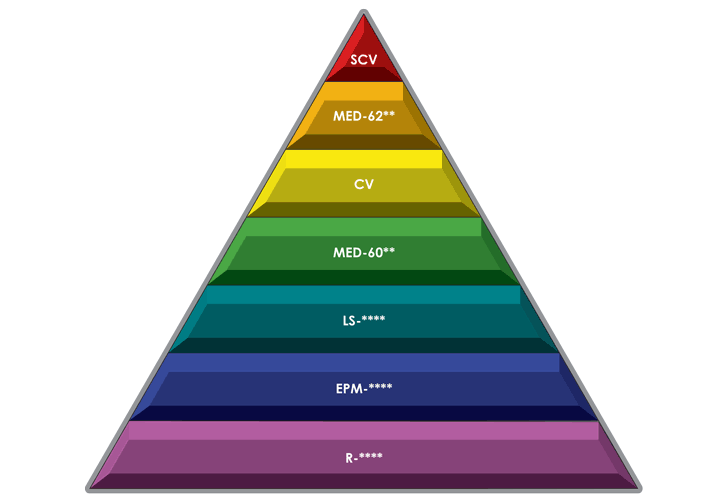

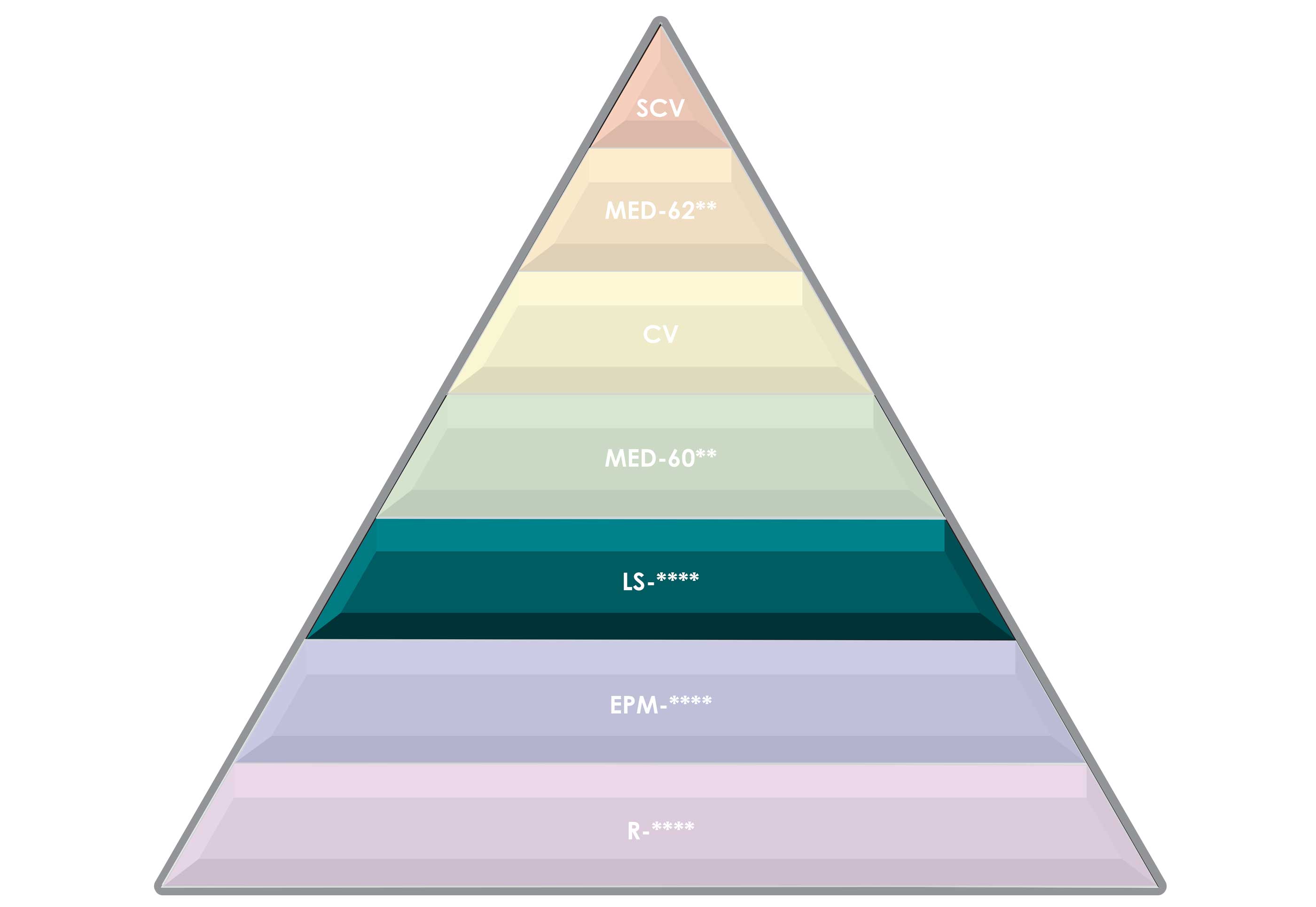

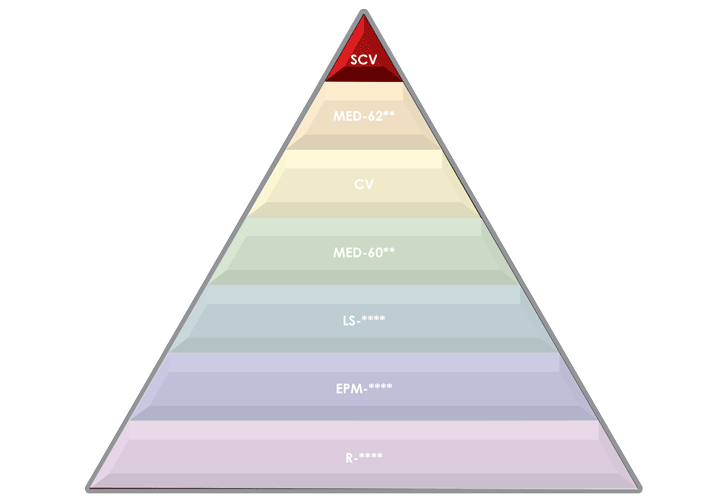

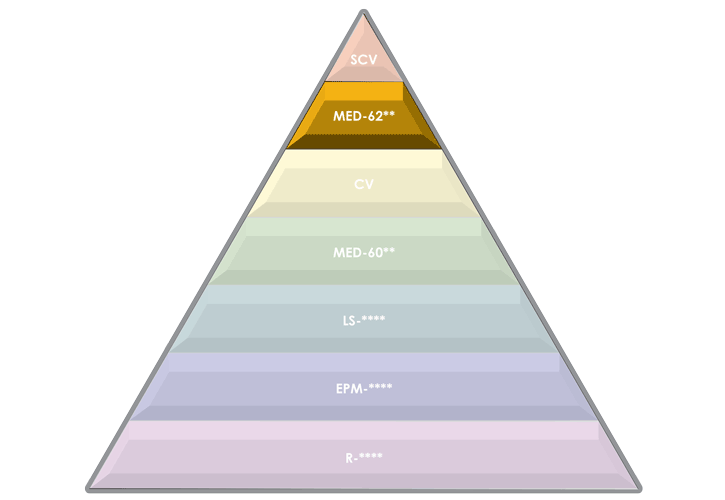

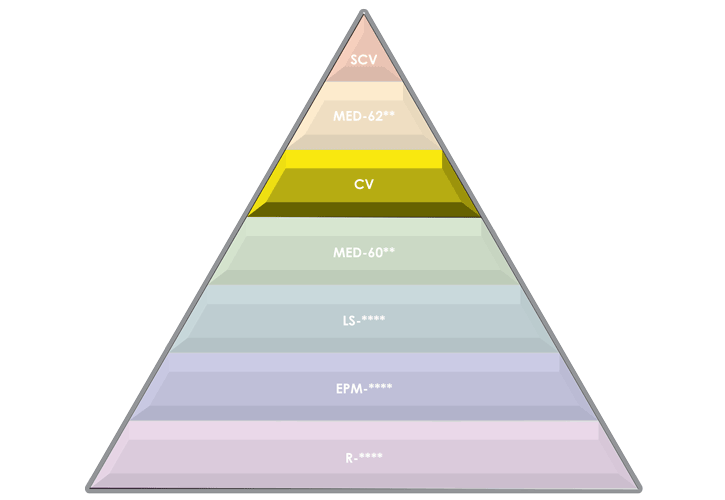

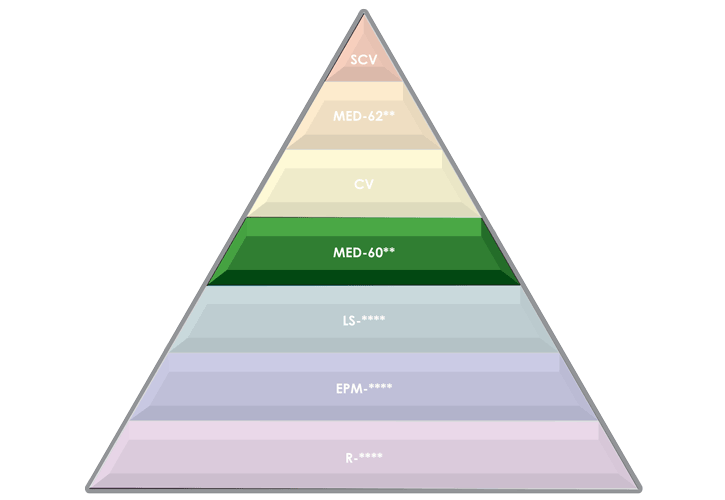

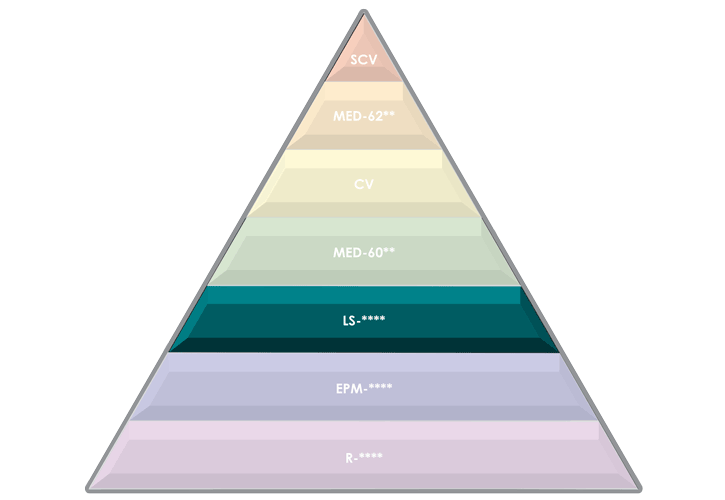

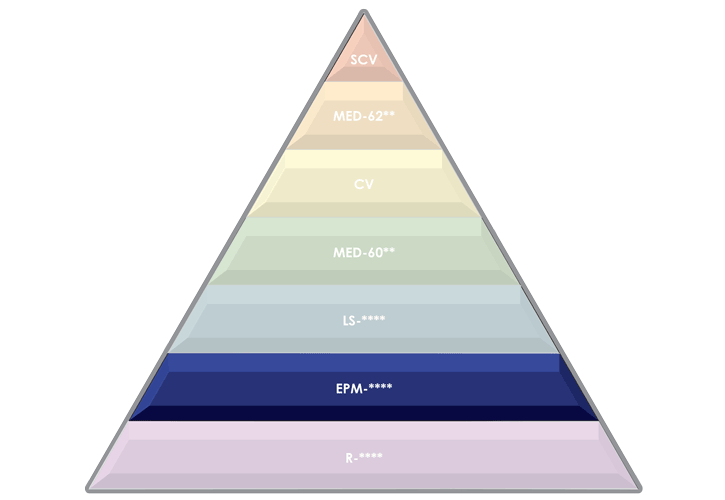

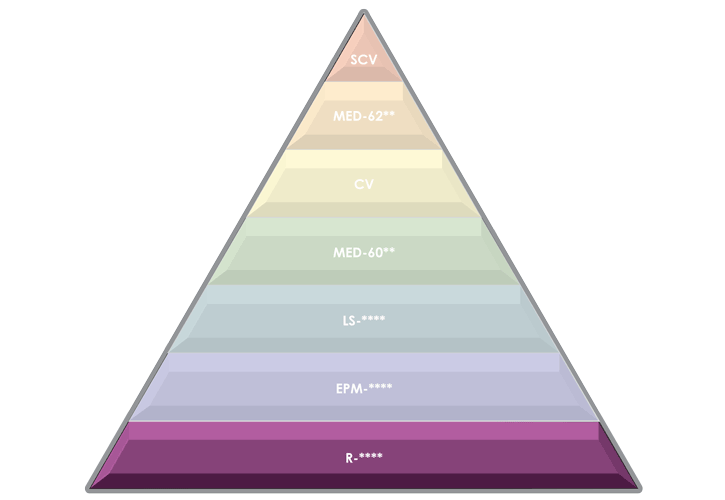

SCV

MED-62**

CV

MED-60**

LS

EPM

R-****

Home